HVAC

Machined & Fabricated Components for HVAC Systems

Billet Industries has long supported many facets of the HVAC industry by manufacturing components used for industrial heat exchangers, commercial & military compressor systems, and pump assemblies for industrial chillers. Our HVAC customers rely on the versatility of Billet’s precision machining services which can accommodate large part geometries. Additionally, our customers rely on Billet’s added value resources for assembly to include AWS certified structural welding of carbon steel (D1.1), aluminum (D1.2), and stainless steel (D1.6). We provide certified subcontracted services to include metal pretreatments, metal finishes, and testing services to include weld inspections and other non-destructive examinations. All of Billet’s manufacturing processes adhere to our certified AS9100 quality management systems ensuring predictable performance for the parts we deliver to our customers. By delivering defect free parts on time, our team ensures you remain cool under the collar.

Industry Details:

- Comprehensive services fabricating components used for industrial heat exchangers, commercial & military compressor systems, and pump assemblies for industrial chillers.

- AWS certified structural welding of carbon steel (D1.1), aluminum (D1.2), and stainless (D1.6)

- Precision vertical CNC milling up to 180 inches in length

- Turnkey manufacturing, testing, kitting and special packaging services to meet your on-time delivery requirements

Case Study

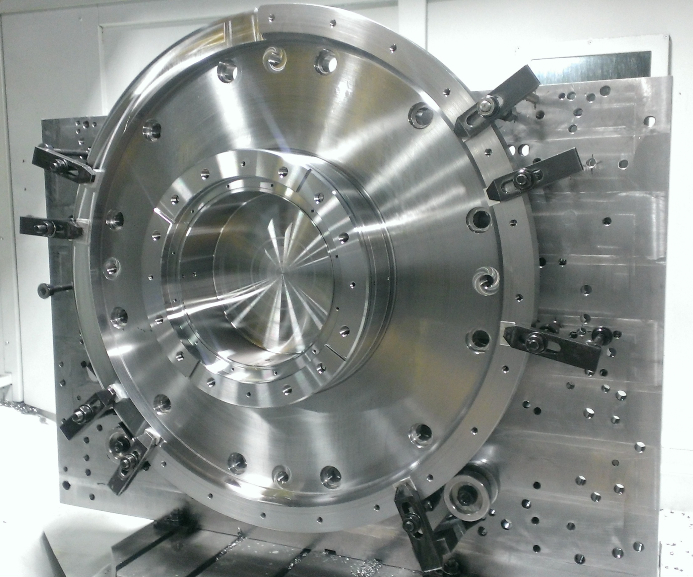

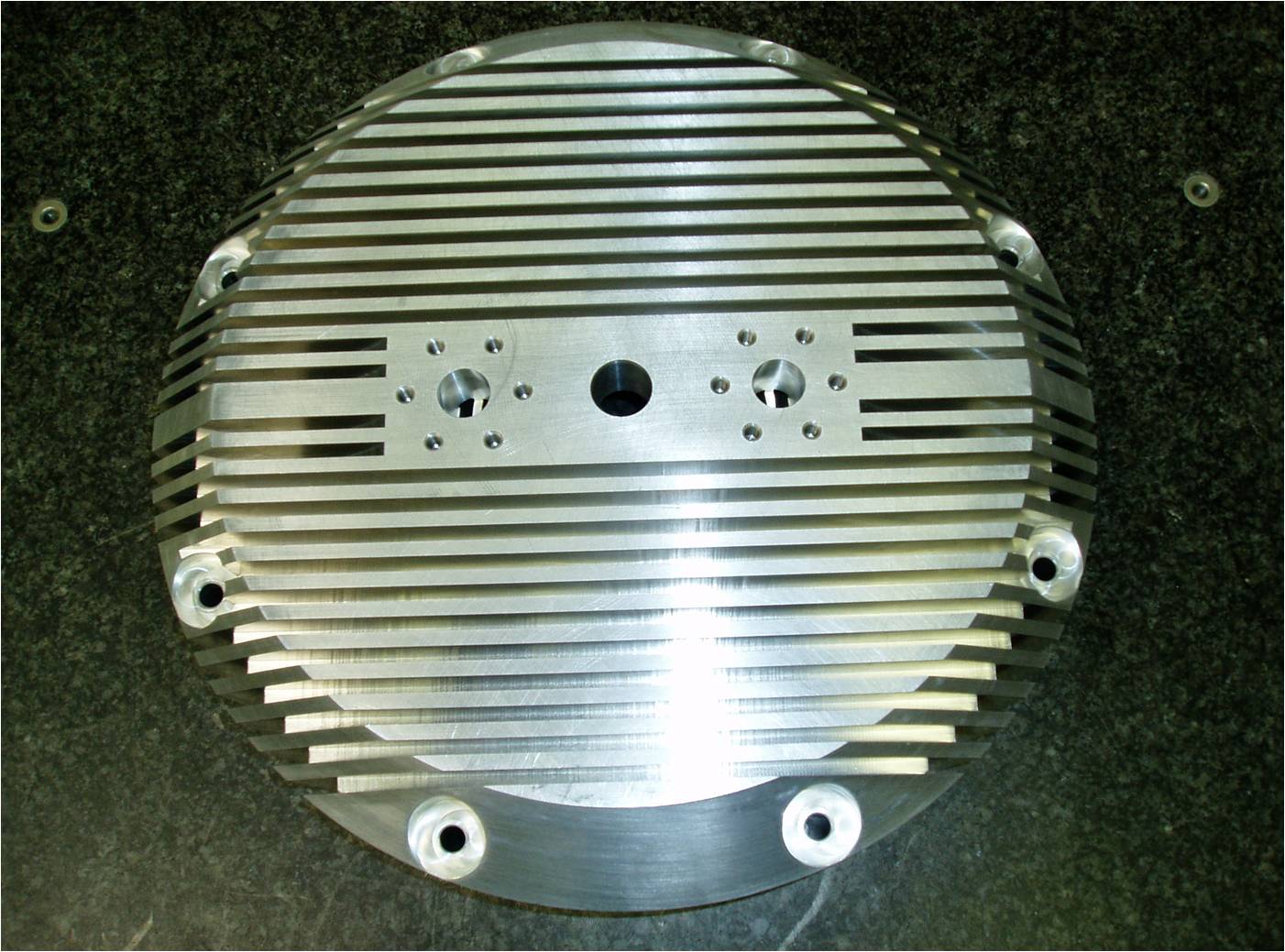

Rotary Vane Pump Assembly

Marine HVAC/Refrigerant Contractor

While HVAC equipment manufacturers continue to reinvest in new technologies and their own manufacturing core competencies, they continue to seek competent contract manufacturers to provide reliable added value resources for their production needs. This is certainly the case with one of Billet Industries’ customers, who produces marine HVAC and refrigeration systems used on naval aircraft carriers, ships, and submarines. For production of a rotary vane pump assembly, Billet was chosen to provide complete, tested assemblies suitable for their own production to integrate into their compressor equipment.

To produce the vane pump assembly, we procured all materials to include castings for machining and mechanical components for assembly. Billet’s incoming inspection ensures traceability of materials and certification that they meet our customer’s specifications. The machining of the casting and subcomponents were performed in-house. In process dimensional and visual inspections ensured that all subcomponents meet the customer’s specifications and that all inspections were performed in compliance to our certified AS9100 quality management systems. At final assembly, we performed a pressure test and ensured all quality documentation is retained for each serialized pump assembly providing full traceability for our customer. These value added services minimize the logistics for subcontracting the material, machining, assembly & testing services separately while minimizing inventory by providing just in time delivery for our customer’s production demands.