Aerospace & Defense

Contract Manufacturing for U.S. Defense Contractors

Trusted Aerospace and Defense Manufacturing Contractor

For over 50 years, Billet has been a trusted supplier for our direct government and sub-tier Aerospace & Defense customer base. We work with Defense Contract Management Agency (DCMA) inspectors before and during the contract and our procedures and services are compliant with important DOD, and Tier 1 contractor specifications.

Industry Overview

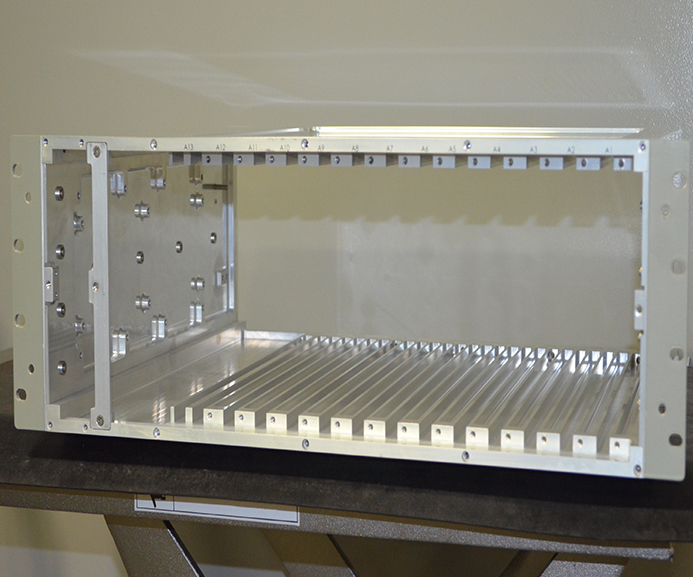

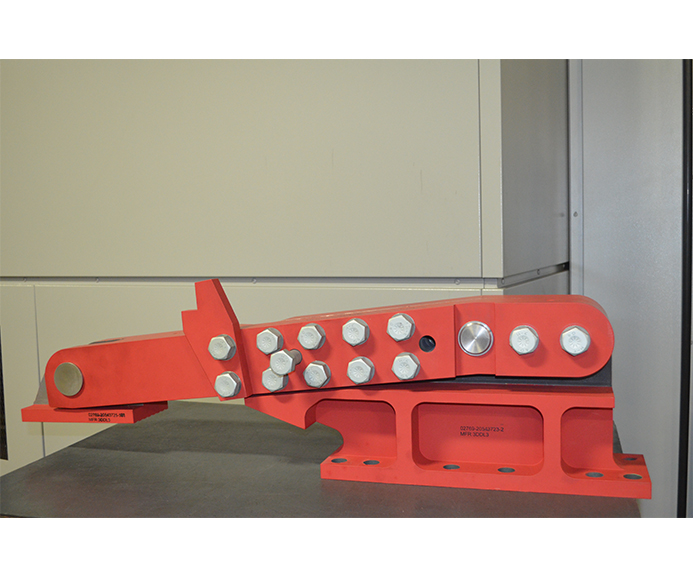

Billet Industries is proud to support the U.S. military and our allies through our contract manufacturing services. At Billet, we offer our precision machining and fabrication services to both the U.S. government and other prime contractors, providing them with defect-free parts and assemblies used on naval surface ships & submarines, aviation systems, and ground combat equipment.

We are experienced in machining and fabricating a wide array of materials, including aluminum, steel, stainless steel, titanium, exotic alloys (including Inconel and Hastelloy®), engineered plastics, and composites. Billet ensures materials and documentation compliance for defense regulated (DFARS) specialty metals. We are experienced in handling customer-supplied, high-valued materials – including Level 1 materials – by providing proven processes and experienced personnel to ensure your part is fabricated right the first time.

Billet Quality

At Billet, all of our processes are quality driven through our AS9100 certified quality management systems, ensuring that we not only deliver defect free parts, but also our customer’s required contract data. Whether this includes certificates for materials or processes, AS9102 formatted first article inspection reports, or specialized inspections & testing reports, we work with military buyers and engineers to meet your exacting standards and demands for building the equipment our military depends.

Industry Details:

- Prime Contractor to U.S. Government as well as other Defense Prime Contractors

- ITAR Registered with U.S. State Department

- Joint Certification Program (DD Form 2345) Cert #0036908

- Experienced fabricating with wide array of materials

- Compliant in sourcing certified DFARS specialty metals

- AS9100D & ISO9001:2015 certified

Case Study

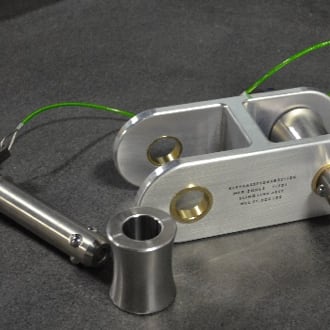

Umark Sling Link Assembly

U.S. Army Aviation

In 2016, Billet Industries was selected as the contract manufacturer for the sling links, lugs, and mechanical assemblies to be fielded as the new U.S. Army Aviation’s Unit Maintenance Aerial Recovery Kits (UMARK). UMARK sling kits are used in the helicopter recovery of disabled aircraft. Previous UMARK designs were bulky, heavier, and were only able to be used on downed aircraft, which still had uncompromised lifting points. Today’s UMARK is lighter, kitted for efficient use, and capable of rigging more severely damaged aircraft including unmanned aerial vehicles (UAVs).

Billet Industries machined, fabricated, assembled, stenciled, proof-load tested, and inspected the mechanical sling links and lug assemblies the aviation teams will use on the new rigging kits. Each sling link and lug assembly required a proof load to ensure structural integrity. All work was performed at Billet Industries York, Pennsylvania facility.